Project Details

Summary

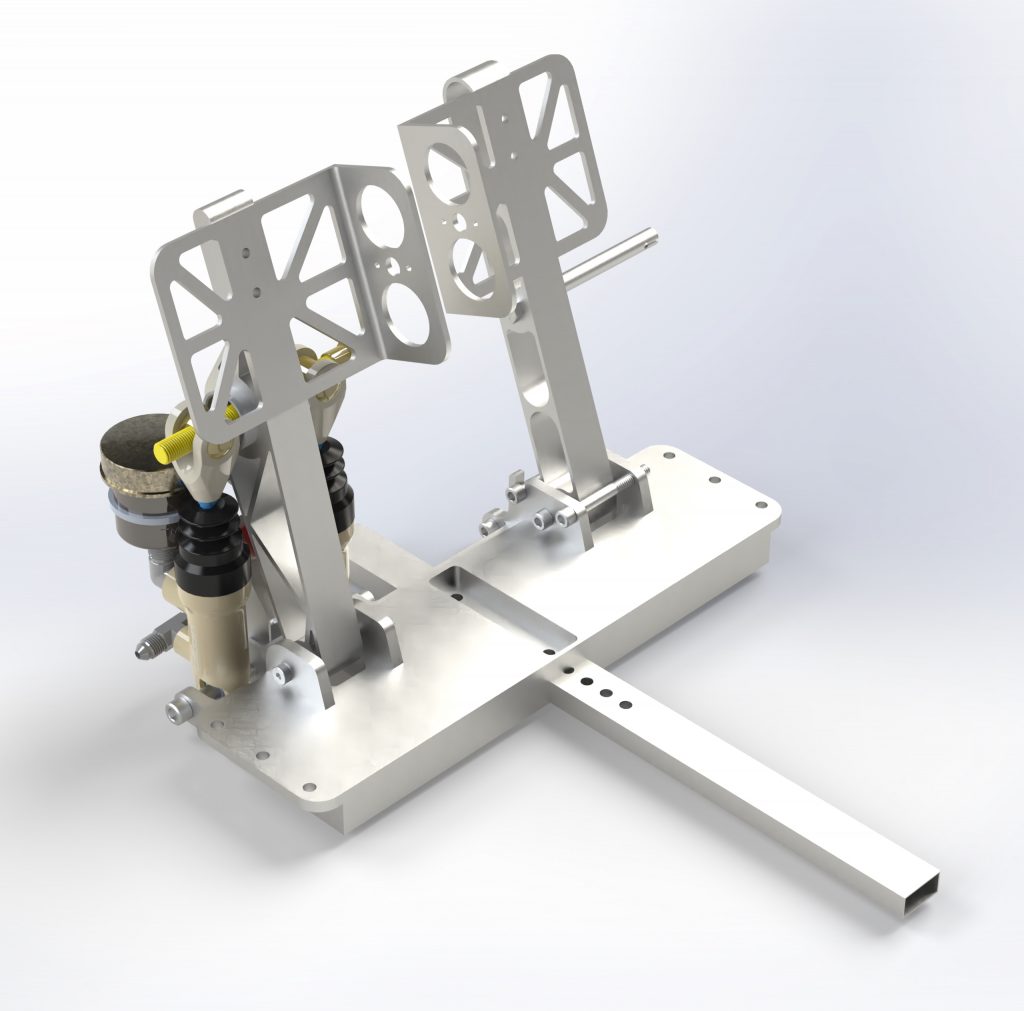

Formula SAE is a competition in which students design, manufacture, and race a 1/3rd scale Formula 1 car within a year. Unlike Formula 1 cars, however, our car needs to be able to accommodate drivers of all sizes in an ergonomic manner. There are two main ways to do this:

- Adjust the position of the driver seat

- Adjust the position of the pedals

Since it is generally more difficult to move the driver, we decided to create an adjustable pedal assembly. To begin the design process, I defined a set of requirements:

- Withstand the 2000 N emergency braking force as specified by the rules

- Allow for the mounting of a brake over-travel sensor as specified by the rules

- Allow for a vertical Master Cylinder configuration to accommodate a shorter chassis

- Maintain a high level of stiffness to ensure driver confidence

- Maintain a mass of 2.5 lbm or under

- Ensure quick adjustability

Brainstorming and Hand-Calcs

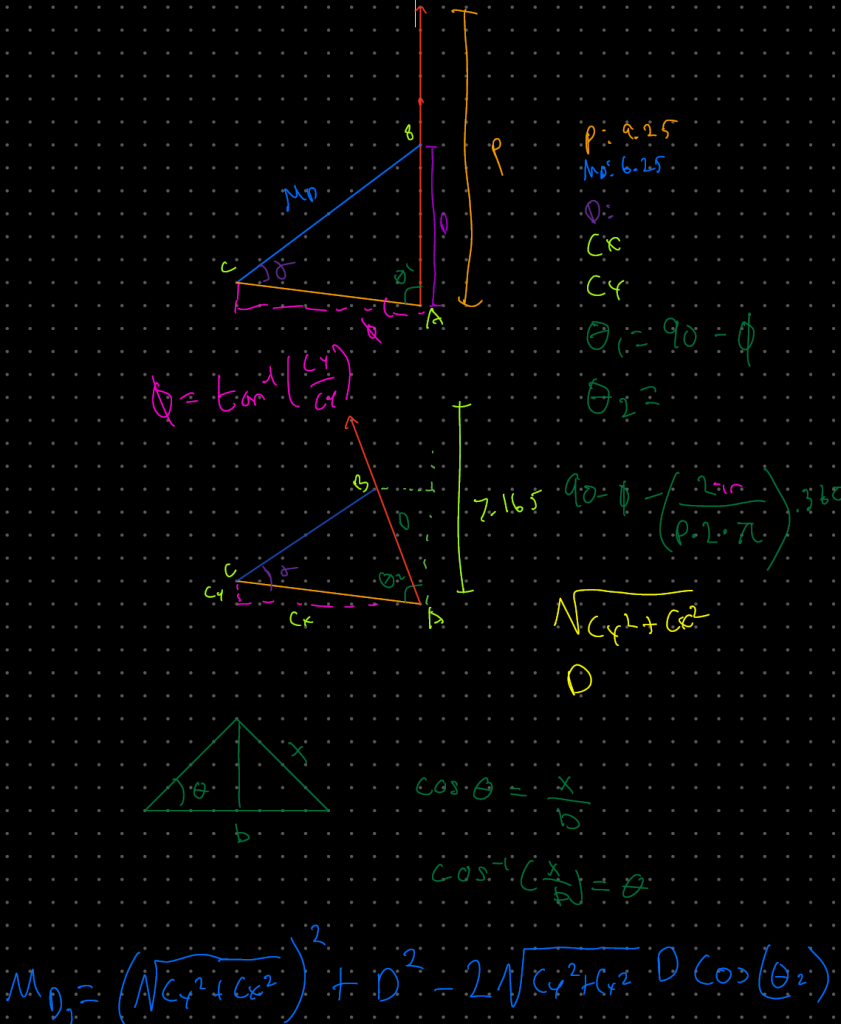

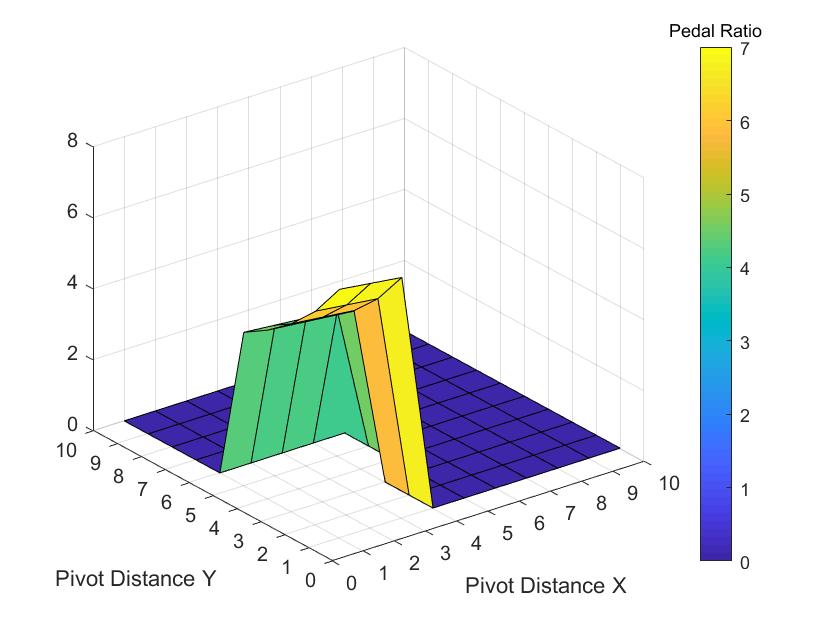

Before running NX, another team member and I researched adjustable pedal boxes, and asked team drivers for their preferences. I then wrote a MatLab script to optimize the pivot point location in order to gain the maximum mechanical advantage for the driver. The script solves for the pedal ratio of all possible geometry configurations and returns the maximum value. The code can be seen below.

MatLab Code

clear;clc;close all; %clear workspace

%//////////////////////////////////////////////////////////////////////////

%initial variable declaration

Pedal_length = 9.25; %Define brake pedal length

Pedal_Start_Angle = 90; %Define pedal start angle based on driver pref

Pedal_Travel = 2; %Define desired travel based on driver preference

Master_StartMin = 5.75; %Define master cylinder max start dimension

Master_StartMax = 6.875; %Define master cylinder min start dimension

Master_EndMin = 5.5; %Define master cylinder max end dimension

Master_EndMax = 6.5; %Define master cylinder min end dimension

Max_Travel = 0.5; %Define Master cylinder desired travel

CXX = linspace(1.5,4,10); %define search matrix gran w/ respect to x

CYY = linspace(-1,0.5,10); %define search matrix gran w/ respect t to y

D = linspace(5,8,25); %H distance search matrix

%CXX = 1.5; %Fix X if neccesary

%CYY = -1; %Fix Y if neccesary

%D= 5.75; %Fix D if neccesary

%//////////////////////////////////////////////////////////////////////////

%main function run

A = run_matrix(Pedal_length,CXX,CYY,D,Pedal_Start_Angle,Pedal_Travel...

,Master_StartMin,Master_StartMax,...

Master_EndMin,Master_EndMax,Max_Travel); %Run search script

Max_Pedal_Ratio = max(A,[],'all'); %search for max value

[x,y,z] = find(A == Max_Pedal_Ratio);%display maximum value based on indiex

B = A(:,:,z); %Truncate array based on max A

hold off; %ensure plot over is off.

surf(B,'MarkerFaceColor','g'); %plot results

xlabel ('Pivot Distance X'); %set x label

ylabel ('Pivot Distance Y'); %set y label

hcb = colorbar; %enable colorbar for visibility

set(gca,'XLim',[0 10]); %Xbox Limit

set(gca,'YLim',[0 10]); %Ybox Limit

set(gca,'XTick',[0 1 2 3 4 5 6 7 8 9 10]); %X tick spacing

set(gca,'YTick',[0 1 2 3 4 5 6 7 8 9 10]); %Y tick spacing

title(hcb,'Pedal Ratio') %Chart title

%//////////////////////////////////////////////////////////////////////////

%Function for matrix level multiplication

function [result] = run_matrix(P,CXX,CYY,D,S_Angle,P_Travel,...

Master_StartMin,Master_StartMax,Master_EndMin,Master_EndMax,Max_Travel)

Cx_length = size(CXX,2); %Store array size

Cy_length = size(CYY,2); %Store array size

D_length = size(D,2); %Story array size

for i = 1:Cx_length %CX layer cycle

current_Cx = CXX(1,i);

for j = 1:Cy_length %CY layer cycle

current_Cy = CYY(1,j);

for k = 1:D_length %D layer cycle

current_D = D(1,k);

A(i,j,k) = crunch(P,current_Cx,current_Cy,current_D,S_Angle,...

P_Travel,Master_StartMin,Master_StartMax,Master_EndMin,...

Master_EndMax,Max_Travel); %Send to geometry solver

end

end

end

result = A; %Return result

end

%//////////////////////////////////////////////////////////////////////////

%Function for pedal box specific calculations

function [ratio] = crunch(P,CXX,CYY,D,S_Angle,P_Travel,Master_StartMin,...

Master_StartMax,Master_EndMin,Master_EndMax,Max_Travel)

phi = atand(CYY/CXX); %calculate sub angle of pedal

theta1 = S_Angle - phi; %gives anti-travel

travel = 360*P_Travel/(P*2*pi); %Calculates possible travel

theta2 = S_Angle-phi-travel; %Calculates depressed angle

CA = (CXX*CXX + CYY*CYY)^0.5; %pythagorean theorem for length

MC_Initial = ((CA^2) + (D^2) - (2*CA*D*cosd(theta1)))^0.5;

%initial master cylinder length calculation

MC_Final = ((CA^2) + (D^2) - (2*CA*D*cosd(theta2)))^0.5;

%final master cylinder length calculation

travel = MC_Initial - MC_Final;

%Travel distance check

%Check if master cylinder can physically achieve travel otherwise 0

if ((MC_Initial < Master_StartMin ) ||(Master_StartMax < MC_Initial))

ratio = 0;

elseif ((MC_Final < Master_EndMin ) ||(Master_EndMax < MC_Final))

ratio = 0;

elseif travel > Max_Travel

ratio = 0;

else

ratio = P_Travel/travel;

end

end